Proofing is the first step of production

Every lapel pin order goes through electronic proofing as the first step of the production process. Digital proofing ensures the final product's correct implementation, colors, and proportions.

Proofing is done for all orders in our domestic production in Helsinki, Finland, to get the process started quickly and, if necessary, be able to communicate directly with the proof designer about any changes. All proofing is done in Finland because it allows us to speed up the transition to production once you have accepted the proof.

Some operators commission design of pins in China, which means slower production time: any change to the printout must be resubmitted to the factory for processing. This time increases the production time.

When you order pins from us, you employ domestic graphic professionals who design lapel pins and implement your requests. The graphics professional also takes care of passing on the technical features to the factory so that the final finished metal lapel pin is as desired.

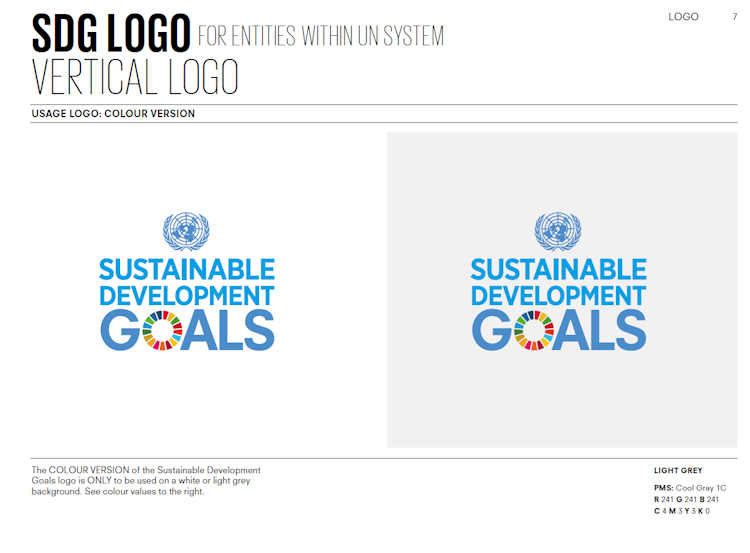

Proof based on graphical guide book

Graphical brandbook included basic elements for the design, along with appropriate color codes required

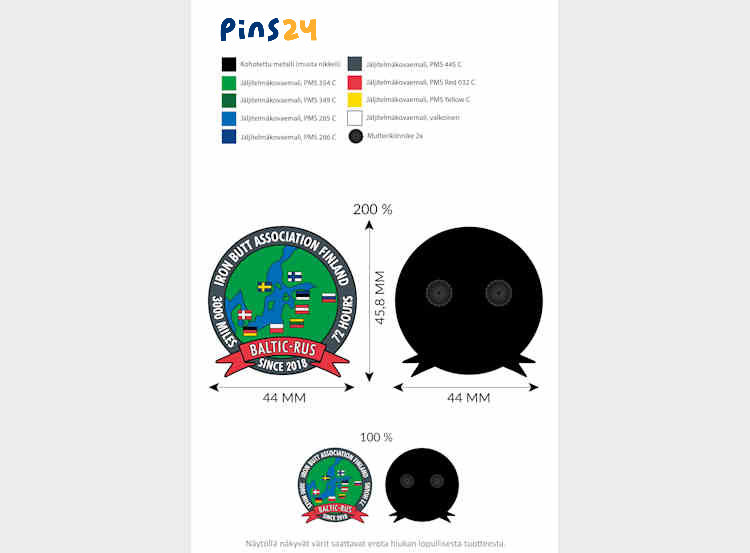

Digital proof made entirely locally by our skilled graphic designers of the final design

Final result of a lapel pin made from the final digital proof created by our talented graphic designers

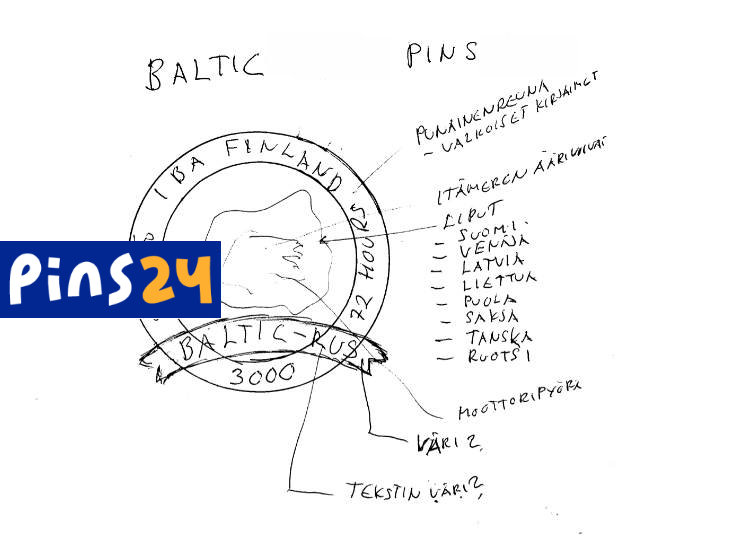

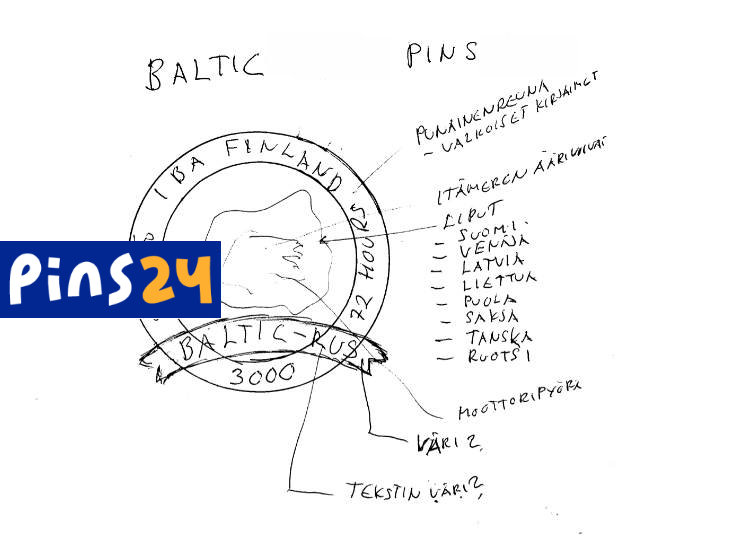

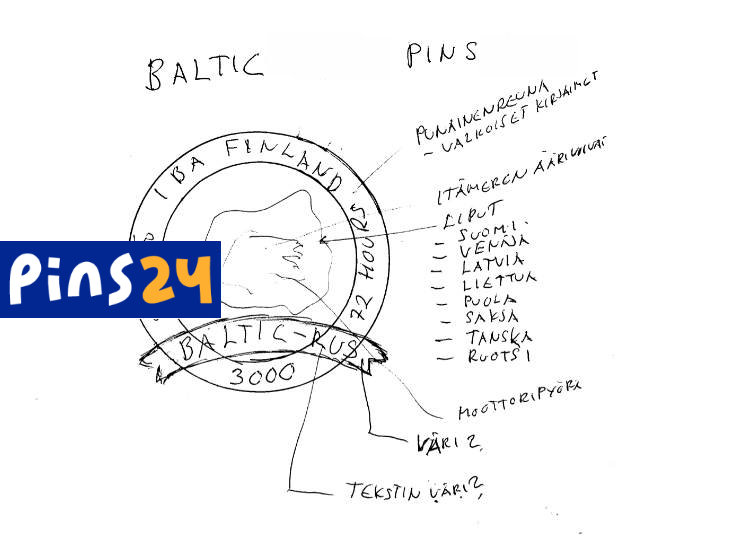

Proof based on a pencil sketch

Hand drawn sketch was supplied with the basic elements, requests and details for the design

Digital proof made entirely locally by our skilled graphic designers of the final design

Final result of a lapel pin made from the final digital proof, including imitation hard enamel and black electroplating

Pins24.com™ is honored to serve some of the finest companies in the world, from recognizable worldwide brands, to reputable local companies.